HEGA (Carbon) Filtration

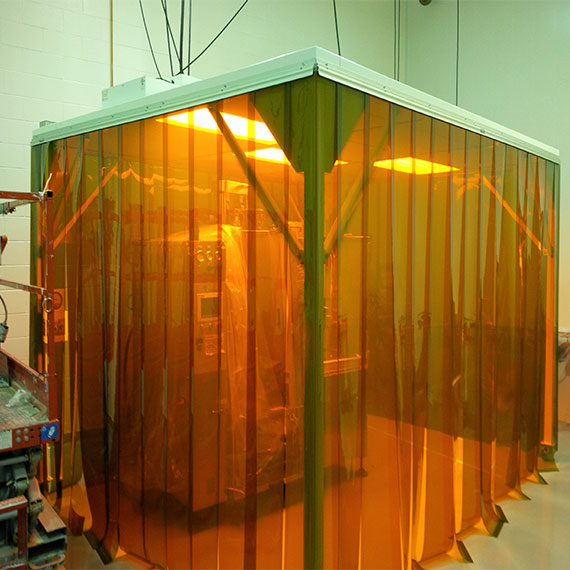

HIGH-EFFICIENCY GAS PHASE AIR (HEGA) filter housings are used where gaseous or VOC contaminants need to be abated. In-line HEGA filter housings can be installed on supply-air ductwork in order to protect a room or area, and they can also be used on return or exhaust ductwork to filter airborne contaminants generated by a process. As the name implies “In-line Housings” are sheet metal enclosures that house modular filters and are placed with duct-connections either on one end or both ends of the filter housing. These sheet-metal enclosures (housings) have one or two doors at either side of the housing, used to install the modular filter elements. These filter housings usually have gaskets and/or mechanicalsealing-mechanisms to eliminate air bypass.

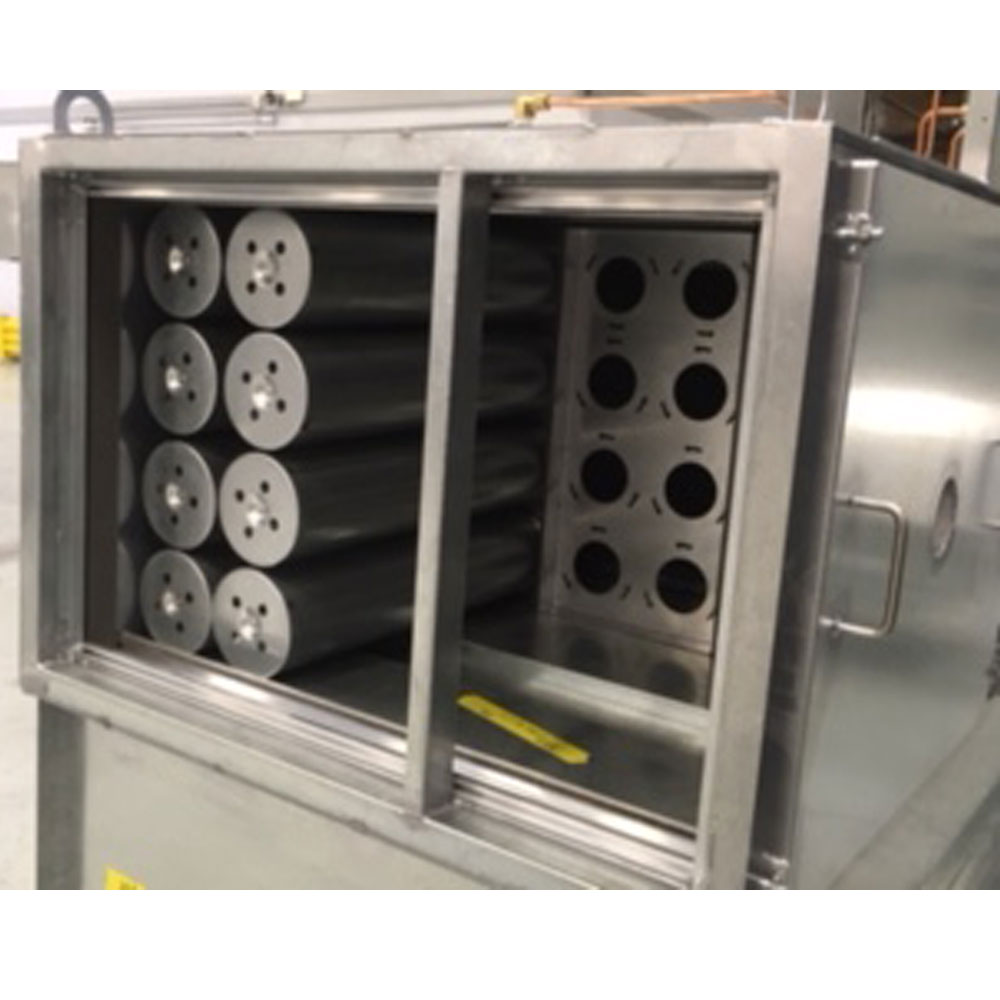

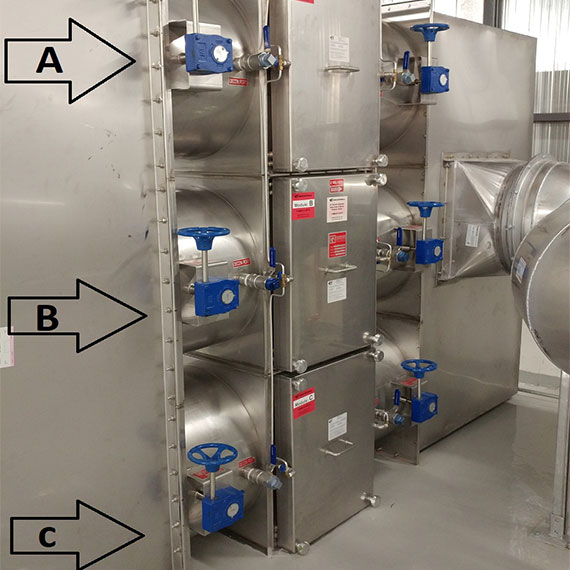

Side-access (in-line) filter housing construction is typically16-gage galvanized-steel, but optional materials include16-gage aluminized-steel or stainless-steel. Material of construction will depend on the application and the physical location of the filter housing. HEGA Filter Housings typically have separate tracks to accommodate ASHRAE MERV8 (or higher) prefiltration, followed by perforated steel trays or cylindrical-canisters containing pelletized or granular gas-phase media. The media applied will depend on the gaseous contaminants that are identified and need to be abated. The HEGA media most commonly appliedfor gaseous or VOC abatement is activated carbon (charcoal). Activated Carbon can also be impregnated with various compounds to abate specific gases and compounds. Activated carbon filters work thru contaminant adsorption.

These HEGA/Carbon filter housings can also be paired with in-line HEPA filter housings on applications where particulate and gaseous contaminants need to be abated.

|

|

|

|

|