Air Showers Ontario

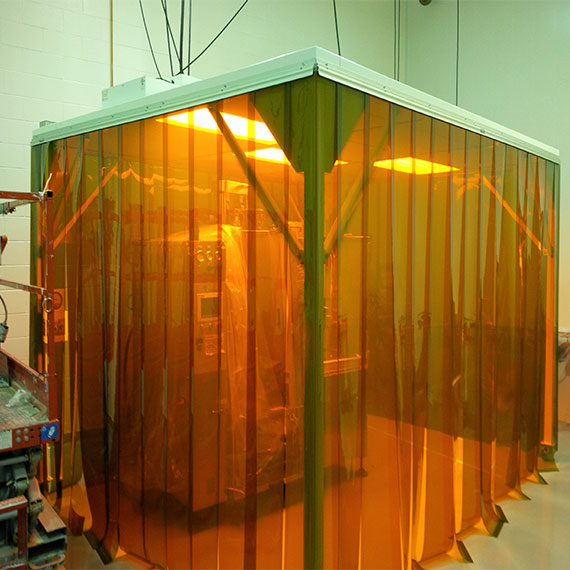

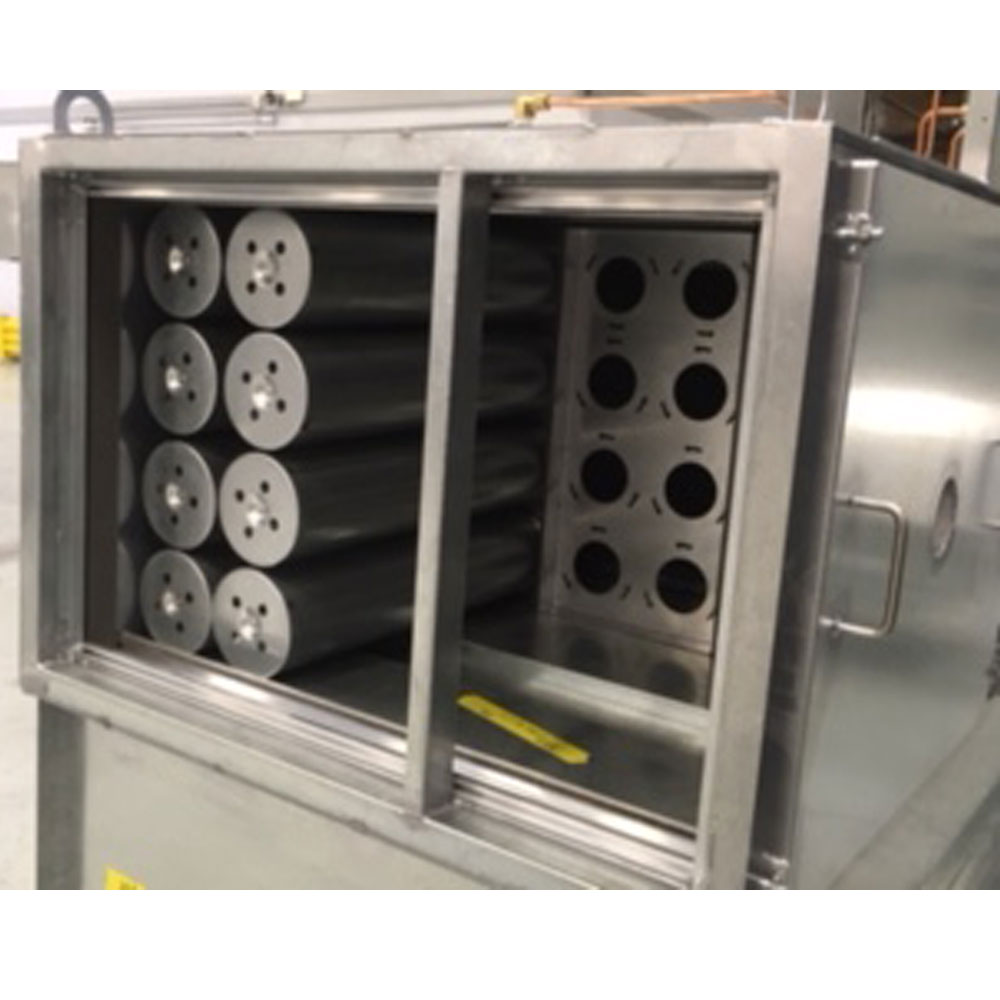

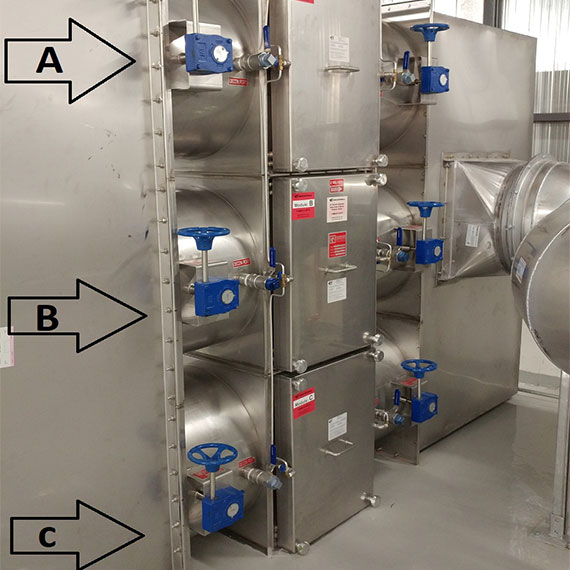

Air showers are specialized enclosed antechambers which are incorporated as entryways to cleanrooms and other controlled environments to reduce particle contamination. Air showers utilize high-pressure, HEPA- or ULPA-filtered air to remove dust, fibrous lint and other contaminants from personnel or object surfaces. The high-velocity (6000-7000fpm) “cleansing” of surfaces prior to entering clean environments reduces the number of airborne particulates introduced. When properly incorporated into cleanroom design, air showers provide an ISO-classified transition vestibule to ensure the cleanliness of the classified cleanroom.

Misting showers have similarconstruction to air showers, and similar purpose in that the intent of the misting shower is to keep contaminants from transferring from one room to another. However, the main difference is that misting showers are used when one egresses the process area, not when entering the cleanroom. Misting showers are employed in cleanrooms where fine powders are likely to be become airborne and settle on personnel and their garments. Misting showers work by delivering a fine atomized-mist that coats the garments worn with the goal of wetting powders that have settled on cleanroom garments. Wetted garments are then carefully removed and disposed, keeping powders from leaving the production cleanroom.

Atmos-tech Industries, one of the largest manufacturers of cleanroom equipment in North America, manufacturesa full range of air showers and tunnels with either epoxy-painted steel orstainless-steel construction.

|

|

|

|