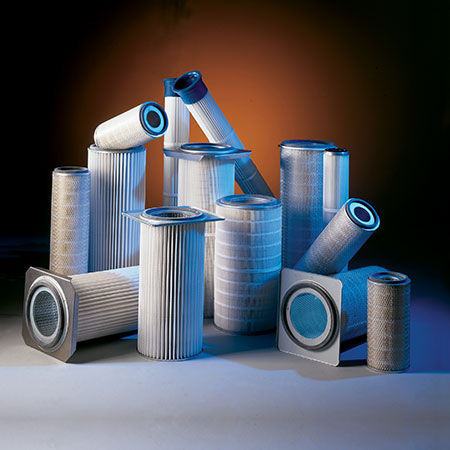

Industry Air Sales Ltd. offers a full range of dust collector components, including dust collector filter cartridges built in Ontario to fit most sizes, makes, or models of dust collectors. These cartridges can be offered from a range of materials from a cellulose blend, fire retardant, nanofiber, spun-bond polyester, PTFE and oleophobic blends.

High-Quality Components for Dust Collector Cartridges

Dust collector cartridges help control pollution and fumes in factories, plants, warehouses, and other industrial or commercial settings to meet the safety requirements in workplaces. With the right components, dust collection systems minimize and remove harmful pollutants produced during the production and manufacturing processes. The equipment is designed to separate and capture particulate matter and dust from the air through the filter and then releases clean, breathable air back into the workplace or environment. Regular filter changes help maintain and improve air quality to ensure a safe working environment and reduce equipment maintenance costs.

With all the filters of dust collectors in Ontario, there are accessories required to make it a complete system. Some of these components are:

- Spark Detection Systems – Our custom-engineered spark detection system is primarily used to detect and suppress sparks and burning embers in dust collectors to prevent a potential explosion.

- Abort Dampers – Considered the last line of defense against fire and explosion. It works by diverting and expelling air back into the atmosphere as soon as it detects an anomaly.

- Exhaust Fans – A dust collecting system needs a fan to move contaminated air from a dust-producing machine.

- Inlet Blowback Dampers – Inlets of hazardous collectors use blowback dampers to limit exposure of harmful of air contaminants. Also known as an explosive isolation device, this component helps prevent re-entrainment from occurring when the blower is switched off. It also ensures the presence of a seal in case of fire, as it stops the smoke from getting back to the shop through the ductwork.

- Motor Control Panels

- Emission Monitoring Systems – This component is designed to detect dust, fine powder, pellets, granular, and mists before emission become visible. Additional, emission monitoring systems prevent valuable powders from escaping and ensures your company meet the regulatory requirements.

- HEPA Filter Systems – It is used to provide a higher degree of filtration efficiency to remove and control harmful indoor particulates. Customize the dust booth to suit your specific size requirement.

- Variable Frequency Drives with Pressure Monitoring Controls – Variable frequency drive (VFD) helps optimize airflow in the dust collector while the pressure monitoring controls provide an accurate measurement of the pressure to detect minor problems.

- Pulse Control Systems – It eliminates the needs for external devices (e.g. pressure switching, relays, and other timers.) It helps dramatically reduce operating costs.

- Spare Parts for all Makes and Models

Industry workspaces produce a significant amount of dust every day, causing air pollution that can pose a risk to anyone in the area. Airborne dust particles are a major concern for a number of business owners. Frequent exposure to dust can increase dust-related disease risk (e.g. cancer, asthma, allergic alveolitis, and irritation).

To effectively prevent air pollution and protect any individuals working in the production area, choosing the right dust collector cartridge system in Ontario is a crucial consideration for any industry. Improving the air quality, coupled with the general environmental concerns in your establishment, makes choosing a high-quality dust collection system of paramount importance.

Manufacturers of dust collecting filters trust Industry Air Sales Ltd. With more than five decades of experience in combined industrial filtration, IAS provides industrial plant operators with long-term solutions to air pollution. Provide a clean and dust-free workspace environment for everyone. Call us at (905) 458-8900 or fill out our contact form to learn how our dust collector cartridges in Ontario help boost productivity and manufacturing efficiency.